Manufacturing Process

With a motto of “Safe and Reassuring”, we constantly control the quality of our products.

Water from Mount Fuji

Water is sourced from our company-owned well located within the Fuji-Hakone-Izu National Park at the foot of Mount Fuji in Fujiyoshida City, Yamanashi Prefecture.

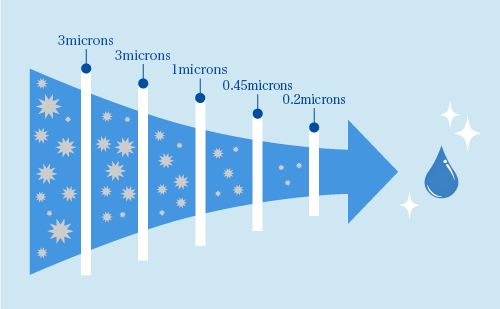

Non-heated Sterile Filtration

We remove most bacteria and contaminants by passing the water through multiple layers of filters, to deliver

safe and reassuring products.

In addition, bacteria below 0.2 microns have never been

discovered on earth.

Bottling into a molded PET bottle

VanaH is manufactured in a near-aseptic condition at one of the best clean rooms in Japan.

VanaH production plant is maintained in a near-aseptic condition, exceeding the conditions

of food production plants. Our factory satisfies as class 100-1,000 clean room (a NASA standard representing air

purity).

- Rinser for Sterilization and Rinsing

- Bottles are sterilized with electrolyzed water and rinsed with the same water used for the product (Hydrogen Silica Natural Water, VanaH).

- Equipment to Sterilize Bottle Openings Using UV Light

- Sterilization is performed by irradiating the bottle's neck of screw part from the outside with strong

ultraviolet/UV light.

As a result, together with rinser-based sterilization, we can achieve complete sterilization on both the inside and the outside of the bottle.

- Filling Machine and Capper

- Filling and capping are performed in a completely sterile environment. At VanaH, the filling water never comes into contact with air, ensuring full-fill filling. It guarantees high product safety and allows us to deliver high-quality products.

Labeling process

Small tack stickers (simple eco-label) are attached to bottles by sliding them sideways onto the bottled

product.

They are carefully attached one by one to finish the VanaH product.

Inspections

The finished goods is checked for water content, cap and tack sticker (simple eco-label) misalignment by an

ultra high performance appearance checker.

Finally, products that have cleared the high

level inspection of the appearance checker will be checked more strictly by the eyes of the inspectors.

Because we are particular about taste and contents, we will not compromise the appearance

of the product.

Packing into Cardboard Boxes

Products which have completed the final check are packed in cardboard boxes.

It is packed

two boxes of 1.9-liter- product which contains 12 bottles at once, passing a weight checker (weighting machine)

twice, and then shrink wrapped with two tea chests as one set.

Delivery to Our Customers

The finished products are safely stored in our brick warehouse, which is highly durable and resistant to

disasters, until they pass a rigorous final inspection.

In addition, we are delivering

only the products that have been cleared to the strict inspection to the customer.

In this

manner, our product VanaH is produced without touching the human hand directly which is our basic concept of

security and safety.

"We wish everyone to drink the secured water, VanaH, with a peace of mind"

It is

contained our best will in the water VanaH.